Orbital Gearing vs Spring Assist

Orbital gearing and Spring assist are two effective methods used to help operate a large or heavy roller blind. They also provide a smoother operation for smaller & larger blinds alike.

Orbital gearing

Orbital gearing refers to the workings inside of the roller blind mechanism.

This uses the basic principle of a lower gearing to help reduce the amount of the effort required to lift a roller blind. For example you can have a 1 to 1.5 gearing in a mechanism. So if you pull the control chain by 10cm then with 1:1.5 gearing the blind would rise by only 6.66cm. This reduces the required input effort meaning that it is possible to operate larger blinds easier.

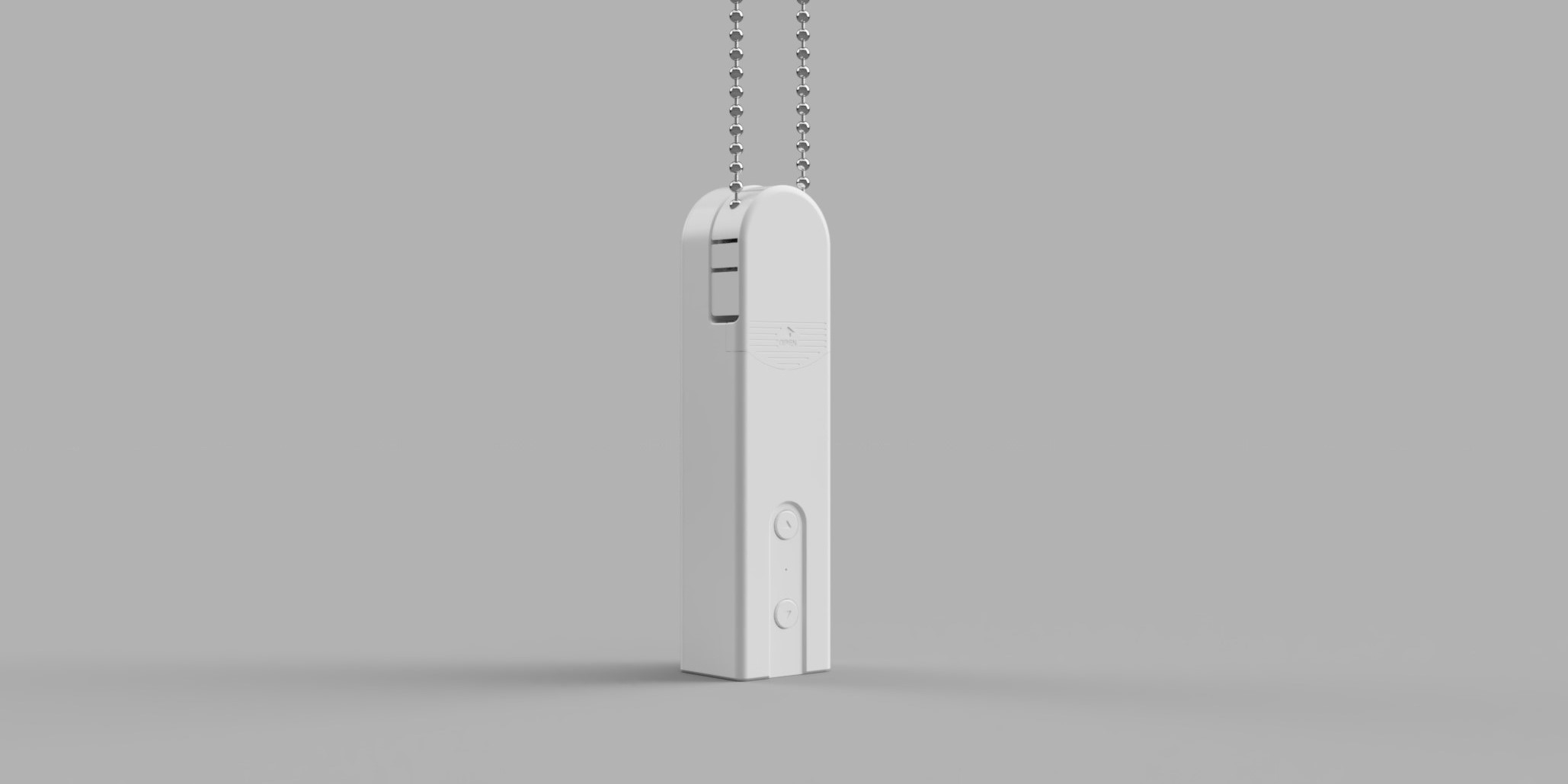

Geared mechanism

Non-geared mechanism

Technical Example

If you take a 3m x 3m roller blind with 3% screen fabric. The weight of the fabric cover with the bottom weight bar would be approximately 5.5kg. To lift this with 1 to 1 gearing (a regular roller blind mechanism) you require a force of approximately 53.9 newtons. Using a 1 to 1.5 gearing this force reduces to 35.93 Newtons. So that represents a 33% reduction in required force.

Spring assist

This refers to a large spring which is inserted inside the roller tube and is connected to a regular 1 to 1 roller blind mechanism.

This method is more about assisting the lift rather than using physics to reduce the required force.

As the roller blind is lowered it is assisted by gravity so heavier roller blinds are actually easier to lower. Spring assist uses this to its advantage and effectively stores this energy up and dispenses it when the blind is raised. Every rotation of the roller tube whilst lowering the blind tightens the spring up. Therefore when the roller tube is rotated in the opposite direction (i.e. when it is raised) the operation is assisted by the fact the spring is being unwound and releasing tension.

This stored energy in the spring is not enough to raise the blind on its own but it does assist the operator.. This results in less force being required by the operator thus making it possible to raise larger and heavier blinds.

Cost comparison.

This dependings very much on the system manufacturer but in general a 1:1.5 orbital geared mechanism would be less expensive than using a standard mechanism with a spring assist inside the tube.

References

Calculator used to calculate force https://www.omnicalculator.com/physics

Acceleration of Gravity is 9.8m/s² according to this article HERE

Please click below for a quote.